OBSERVATION 8: WEEK 2 MAR 2018

PROLOGUE

The East End Transformation Project is the largest capital project ever undertaken on the Danforth Campus. It will also be the most disruptive. The following is a terrain map and schematic development map helping one locate the extent of the project and understand its various components respectively.

THE SETUP

The following plan depicts the location of the cameras mounted on permanent structures along the periphery of the site. These permanent structures are the Brookings Hall, Green Hall and Hillman Hall respectively. The daily feed from these cameras are employed to track and monitor construction progress.

PROGRESS DOCUMENTATION

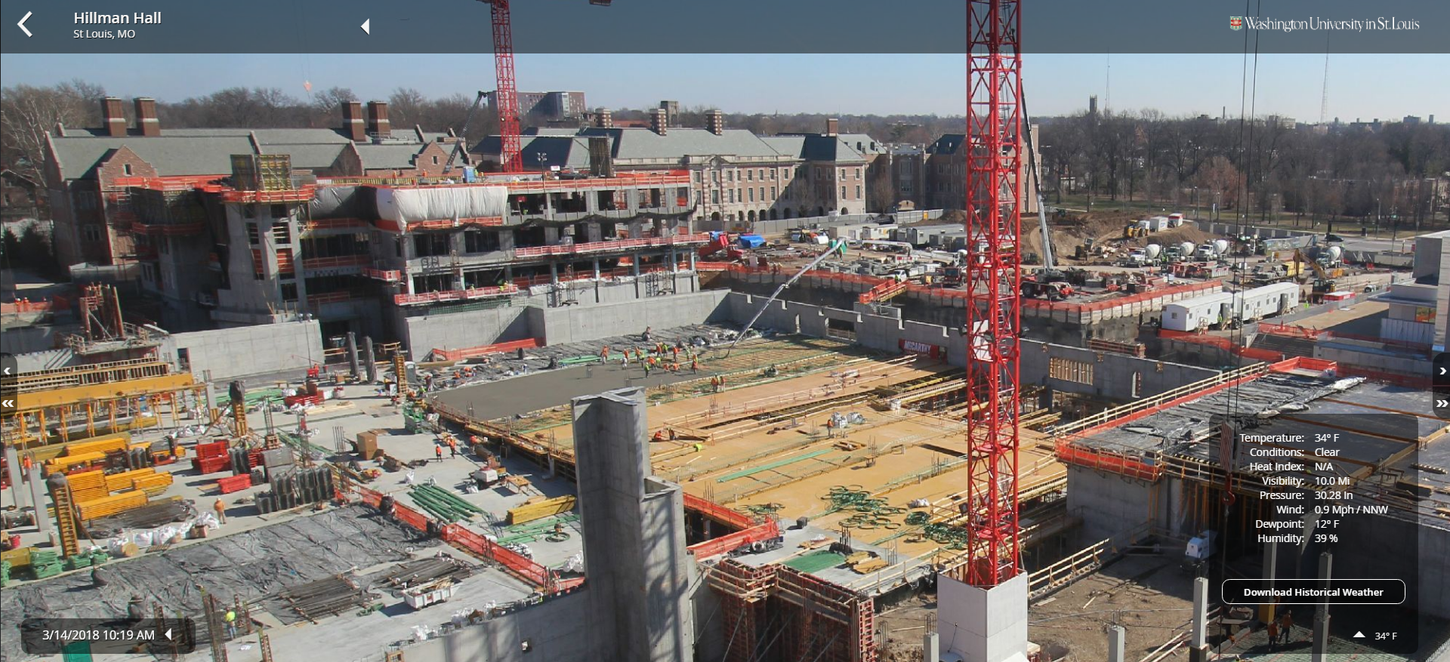

The following section depicts the observations undertaken at the construction site with a focus on project progress, construction activities, materials, equipment, workers, and site conditions. The order of photographic documentation is the perspective from Brookings Hall, Green Hall and Hillman Hall respectively. Each unique photograph is followed by a comparative to depict progress compared to the preceding work week.

This research will be confined to observing the construction progress of the Henry A. and Elvira H. Jubel Hall (3) and the Underground Garage (8) for the 2nd week of March 2018.

EQUIPMENT MOBILIZED: Tower Crane (#3), Truck-Mounted Concrete Boom Pump(#3), Linkbelt 8090 Rough Terrain Crane(#3), CAT 305.5E2 CR Mini Hydraulic Excavator(#2), Bobcat Compact Track Loader(#3), Telehandler(#4), CAT CP44 Vibratory Soil Compactor(#2), Articulating Boom Lift(#3), Mast climbing work platform(#5) etc.

CONSTRUCTION ACTIVITIES:

-

Underground Garage :

-

North End: Level 1 Slab formwork assembly (Post-tensioned RCC slab);

-

North End: Level 1 Slab rebar assembly from construction joint 6 until construction joint 8 (Post-tensioned RCC slab);

-

North End: Retaining Wall construction and waterproofing;

-

North End: Soil backfill and compaction;

-

South End: Level 0 Ramp construction (RCC columns);

-

South End: Level 1 Slab concrete pour from construction joint 2 until construction joint 3, and from construction joint 5 until construction joint 7 (Post-tensioned RCC slab);

-

South End: Level 1 to Level 2 Retaining wall construction (RCC shear wall);

-

South End: Level 2 RCC column construction;

-

South End: Level 2 Beam soffit formwork assembly;

-

East End: Level 2 to Level 3 Elevator Shaft formwork (RCC Shear wall)

-

Jubel Hall :

-

North End: Level 4 RCC shear wall/Elevator Machine Room formwork assembly;

-

North End: Soil backfill and compaction;

-

South End: Level 4 RCC slab concrete pour;

-

South End: Level 4 RCC shear wall/stairway tower formwork assembly;

-

Level 2 and Level 3 peripheral external masonry in progress.

-

Some concrete placement activities are observed even when the ambient temperature is 34-36 deg. F. This is strange as this scenario falls under the "cold weather" concrete condition as per ACI 306 and hence additional precautions in the form of insulation blankets, heated mix or high air-entrainment might be warranted to ensure concrete strength development and quality concrete placement.

-

Enclosures making use of transparent plastic film and tarpaulin are observed in the Jubel Hall building. This ensures a temperature and humidity controlled environment thus providing comfortable working conditions in winter/cold weather;

-

All labors are found to be wearing PPE and Fall arrestors. Safety Standards for Signs, Signals, Barricades, Trenching, Excavation are observed to be complied with. Also, regularly spaced 20 and 40 Yard waste dumpsters highlight the attention to housekeeping and waste segregation. Safety toolbox meetings were observed and it can be deduced that all construction activities are undertaken in strict compliance with OHSA guidelines.

-

An elaborate traffic diversion plan, as well as the deployment of flaggers along the entrance and exits of the construction perimeter, highlight the attention towards traffic management and minimizing disruption to the university operations.

MANPOWER COUNT: At least 46 labors across Rebar, Concrete, Carpentry (Formwork), Masonry and Common labor trades were observed to be working on site.

CONSTRUCTION MATERIALS: A615 Grade 60 Rebar, Concrete, Engineered Fill, Excavated earth, concrete masonry unit, premixed mortar, Waterproofing membrane, System Formwork (Wall panels, struts, H beams, Plywood, Table Forms, Props etc), Post Tension tendons/cable, Geotextile, Vapor barrier, Plastic tarpaulin, PVC conduits, Electrical Gang box etc.